+86 15589053798

STAY IN TOUCH WITH US

Sollant

TEL:+8615589053798

EMAIL:info@sollant.com

Shanghai Sollant Energy Saving Technology Co., Ltd. is a compressed air system manufacturer integrating R&D, production, sales, and service. Sollant has long been based on the research and development of new technologies strictly follo...

Detailed introduction

Product details:

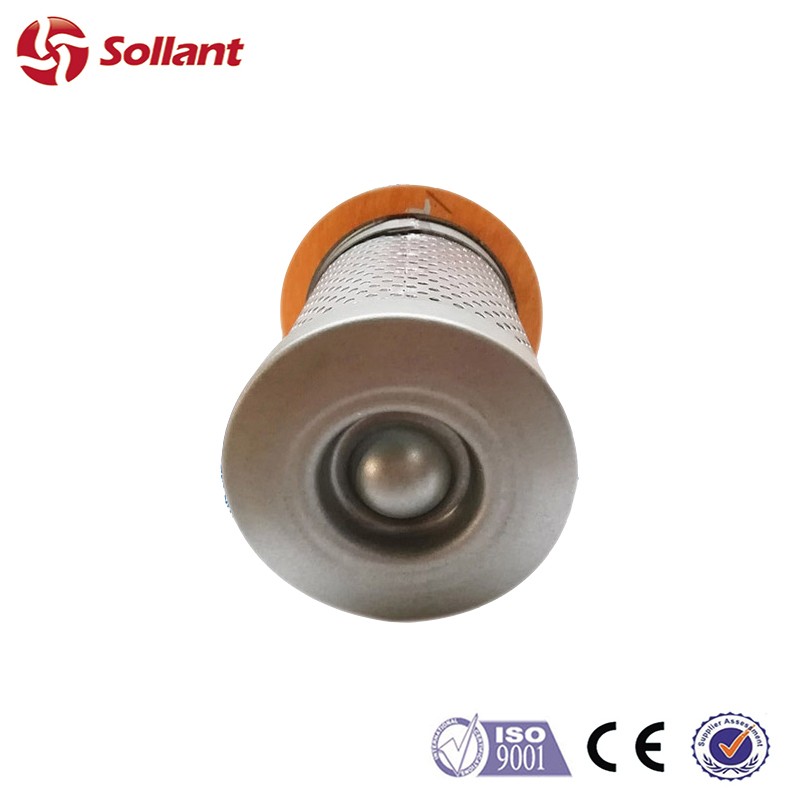

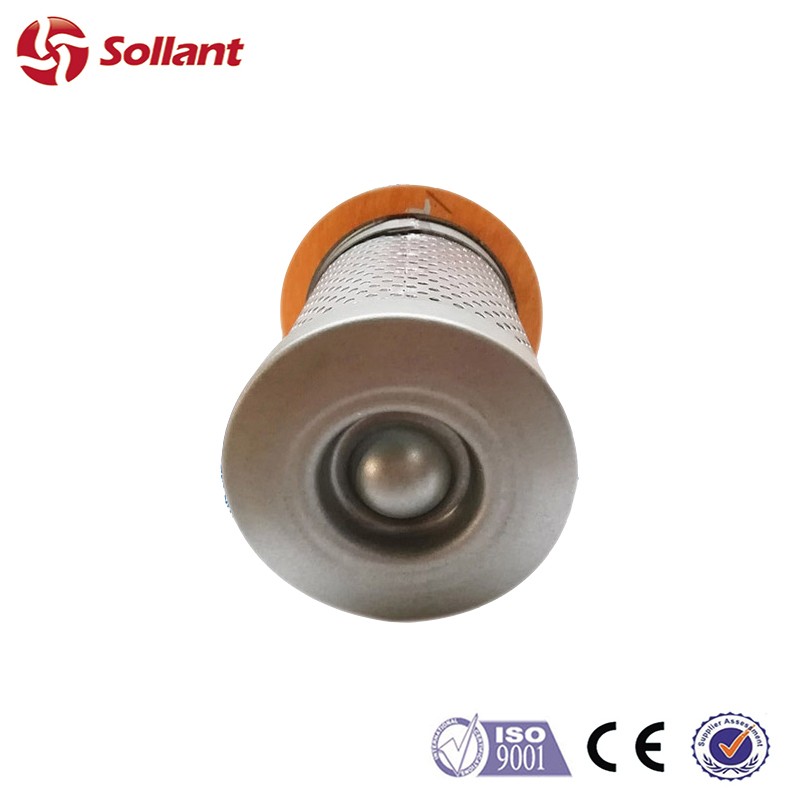

The oil gas separator core is designed for oil and air separation. It contains two kinds of filter elements, namely: polymer filter and separation filter.

The oil gas separator core is a two-layer structure, and the first layer is fine particles made of borosilicate glass fiber having a certain thickness and void. The second layer is made of polyester synthetic fiber.

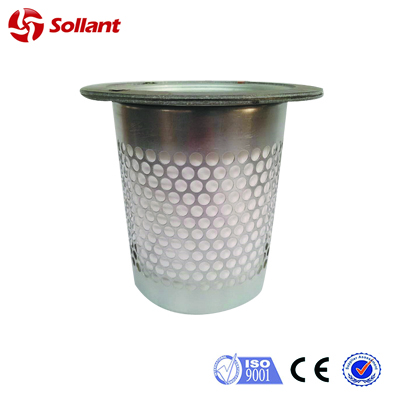

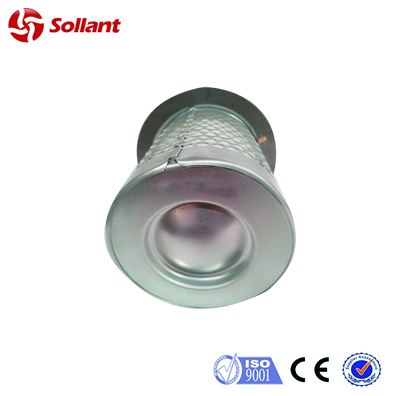

The oil gas separator core Separation Process

The oil-gas mixture of the screw air compressor enters from the tangentially arranged intake pipe, flows tangentially along the inside of the tank and collides in a container composed of baffles, and loads the oil by inertia and gravity. The drip is separated and the oil flows out of the oil pipe. After the coarse separation, the oil and gas mixture enters the oil core for fine separation.

After the crude oil gas separator core separation process, the oil and gas enters the oil separation core for fine separation, and the return oil recovers the residual oil, and the clean gas is discharged from the pressure holding check valve.

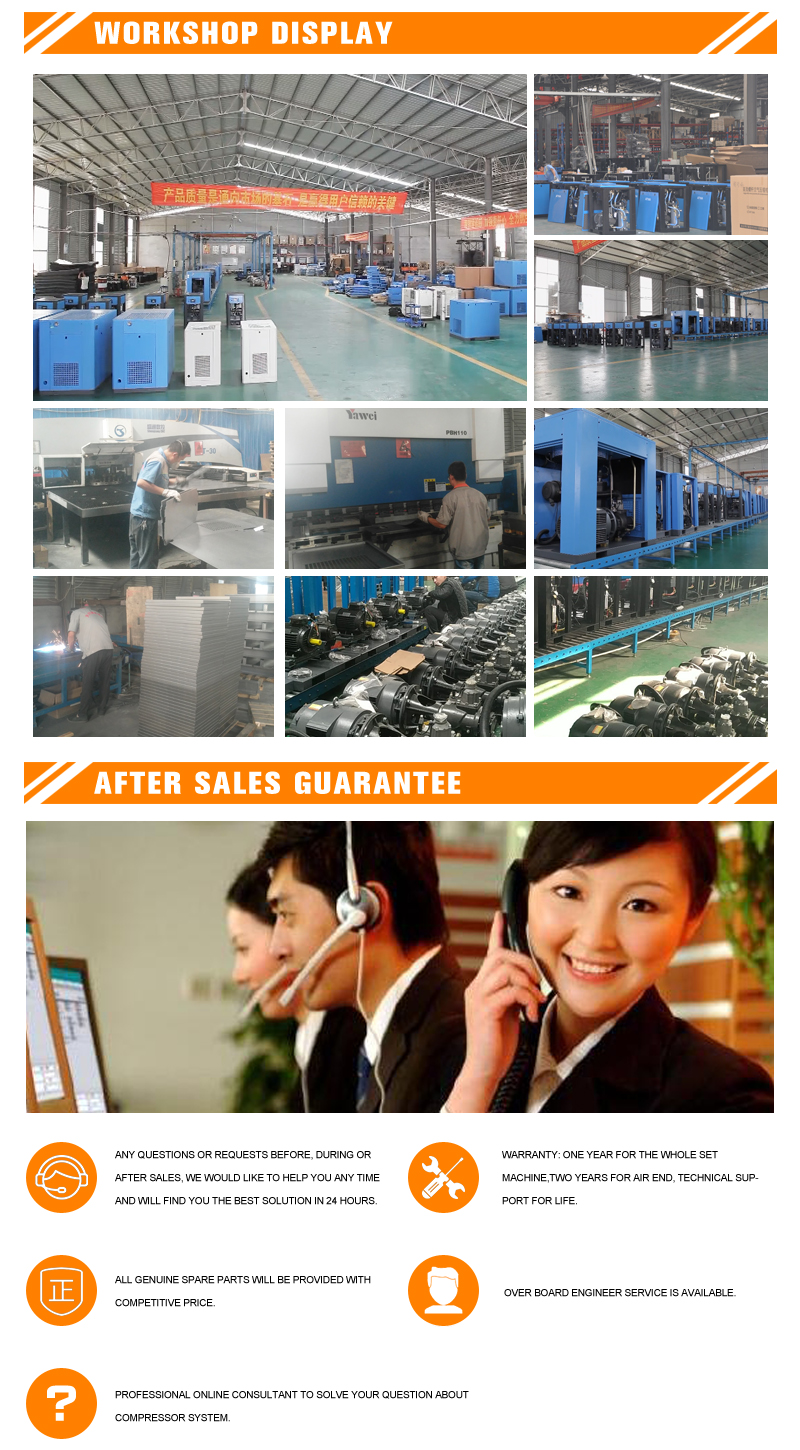

Why choose us

1. Reliability.

Continuous testing for many years can ensure the absolute reliability of permanent magnet frequency conversion.

Fully sealed oil cooling shell can completely prevent dust and liquid.

Optimal performnce fulfill the customer' s need of purchasing the most affordable repairable part.

2. Energy saving.

Campared with non variable speed screw air compressor,it can save 50% energy.

Large displacement. variable frequency range from OHZ to 300HZ the exhaust volume increases as high as 28%.

High efficiency motor (IPM) can up to 94. 5%. and achieve the efficiency level of IE4.

3. High efficiency

Compared with other manufacturers in the production of ordinary frequency conversion machine . our air compressor can save about 6%-7% energy.

In the air compressor life cycle. the total costs are composed of the cost of purchase matainance and energy. Frequency conversion control system can reduce energy consumption, thus reduce the total cost of air compressor .

4. New change

Adopting the new concept of frenquency conversion air compressor achieve the highest energy saving effect in this industry .

More compact design, more closed body, less noise, less floor

Leading the future direction of the air compressor, establishment the industry standards. to provide customers with the value of energy.

How much can you save if you buy our screw air compressor?

Production of compressed air energy consumption may be more thaconsumption, can significantly reduce energy consumption, VS conon actual gas consumption, reduce the additional 44% to 25% of the energy saving program

Special Customized Service

1) Full OEM

Quantity: at least 1 set.

In this plan, we will do all the changes (Color, name plate and logo) as your need, and will not charge extra fee.

2) Half OEM

Quantity: no limit

Under this program, we can make the necessary alteration (name plate and logo) but we will charge some extra fee for the name plate, as the name plate factory has the MOQ.

3) Logo OEM

Quantity: no limit

Only the logo will be changed to yours, and no extra fee will be charged.

Overseas Engineer Service

We are available to send our engineer for aboard service. Only need you to arrange the accommodation, transportation and translator. Extra cost for each will be discussed based on local price level.

English

English Russian

Russian